FLYASH BLOCK (AAC PROCESS)

About FLYASH BLOCK (AAC PROCESS)

Invented in 1920 by Swedish scientist, Mr. John Axel Ericson, FLYASH BLOCK (AAC PROCESS), is a steam-cured cementitious product manufactured from a mix of pulverized fly ash, cement, lime, gypsum and an aeration agent, giving it its unique cellular lightweight internal structure.

Its light weight nature, excellent thermal insulation, acoustic properties and energy efficiency make FLYASH BLOCK (AAC PROCESS) an intelligent building solutions system.

FLYASH BLOCK (AAC PROCESS) combines durability and strength with its extraordinary buildability and superior ecological green features. Its exceptional attributes make it an effective replacement to ordinary red clay and fly ash bricks; making FLYASH BLOCK (AAC PROCESS) the preferred choice for all building applications.

Product Features

Product description

FLYASH BLOCK (AAC PROCESS) have flexible usages and can be used for all kinds of walls, external or internal and non-load bearing walls.UAL’s FLYASH BLOCK (AAC PROCESS) manufacturing unit has been set up at Bagnan in technical collaboration with HESS FLYASH BLOCK (AAC PROCESS) Systems, Netherland, the pioneers in the world for FLYASH BLOCK (AAC PROCESS) machinery.

- FLYASH BLOCK (AAC PROCESS) are highly cost effective due to its durability, High construction speed and its ability to be labor friendly.

- FLYASH BLOCK (AAC PROCESS) are highly Durable because they have excellent resistance to earthquakes & hurricanes and have been proven to withstand wind load of Category 5 tropical storms. FLYASH BLOCK (AAC PROCESS) are also water Resistant because of their unique, micro-cellular structure, with millions of tiny air bubbles that do not interconnect, that form an effective barrier against moisture penetration, resisting the passage of water from the surface. Moreover, UAL FLYASH BLOCK (AAC PROCESS) are impervious to attacks by insects or rotting. They are completely insusceptible to termites.

- FLYASH BLOCK (AAC PROCESS) buildings and walls are built much faster because of the usage of larger blocks with a thin layer of mortar which sets in an hour! They are made with high dimensional accuracy and can be installed using glue instead of mortar for faster construction. FLYASH BLOCK (AAC PROCESS) and panels are lightweight thus ensuring easy workability leading to quicker installations.

- UAL’s FLYASH BLOCK (AAC PROCESS) have high flexibility in cutting / sawing, shaping, nailing and drilling using hand and power tools. Its easy handling, owing to its low density and rapid construction consequently reduces construction labour cost and time.

- FLYASH BLOCK (AAC PROCESS) are available in a varied range of sizes and densities. One FLYASH BLOCK (AAC PROCESS) can cover the same area as up to 12 red clay bricks! FLYASH BLOCK (AAC PROCESS) also offer a wide range of finishing options like tile hanging, timber cladding, brick slip systems or other rendering options (Ceramic tiling, Paint, Dry Lining).

- FLYASH BLOCK (AAC PROCESS) are energy efficient as they have high thermal resistance and thermal mass, which help them maintain temperature and reduce the usage of heating and cooling equipment.

- FLYASH BLOCK (AAC PROCESS) are environment friendly, and no harmful substances are released in its production. Likewise, demolished blocks can also be recycled in the construction process.

- Our FLYASH BLOCK (AAC PROCESS) fall under grade Euro Class-I for non-combustibility and is classified as a non-combustible building material; conforming to the Class ‘0’ rating for the surface spread of flame. These blocks are not only fire resistant, but they provide the highest level of safety and security against fire because they meet stringent fire safety requirements.

- FLYASH BLOCK (AAC PROCESS) are strong and Lighter in weight than normal panels and red clay bricks, thus ensuring that building foundations are lightly loaded yet strong enough to bear several floors. Its lightweight nature contributes to transportation as well.

- FLYASH BLOCK (AAC PROCESS) provide superior sound Insulationowing to the tiny cell structure of its makeup. They also have excellent acoustic performance and can be used as an effective sound barrier for conference halls, IT offices, schools, hospitals, hotels and theatres.

- Since FLYASH BLOCK (AAC PROCESS) are natural insulators, they havethermal efficiency ten times higher than that of aggregate concrete and five times better than clay brick. Thus keeping buildings cool in the summer and warm in the winter. They consequently save installation and electricity costs.

PRODUCT SPECIFICATION

Our state of the art FLYASH BLOCK (AAC PROCESS) comply with all the below specifications that make us an ideal solution for fast, cost effective and modern construction.

| Properties | Value |

|---|---|

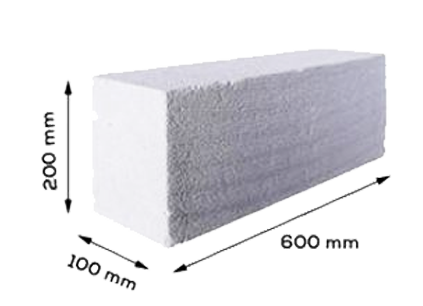

| Sizes Available | 600mm x 200 / 250 mm x 75-300 mm (length x breadth x thickness) |

| Density (Oven Dry) | 551-650 kg / m3 |

| Compressive Strength | >4 N / mm2 |

| Coefficient of Thermal Expansion | ~ 8x10-6 / oK |

| Thermal Conductivity | < 0.24 w/ m.k |

| Drying Shrinkage | < 0.05 % |

| Fire Rating | 4 - 8 Hrs. (for 200mm thickness) |

| Sound Absorption | 45 Db - 50Db |

| Color | Greyish White |

| Product Type: | Density(kg/m3) | Length(mm) | Width (mm) | Thickness (mm) |

|---|---|---|---|---|

| FLYASH BLOCK (AAC PROCESS) | 450 | 600 | 200/250 | 75/100/125/150/ 200/ 250/300 |

| 500 | 600 | 200/250 | 75/100/125/150/ 200/ 250/300 | |

| 600 | 600 | 200/250 | 75/100/125/150/ 200/ 250/300 |

Block Jointing Mortar

KON_CRETE thin bed mortar is a specially designed adhesive to fix FLYASH BLOCK (AAC PROCESS). It is specifically proportioned blend of high quality raw materials such as graded river sand, cement, hydraulic lime and some performance enhancing environment friendly polymers. This mortar is manufactured in a sophisticated factory set up under stringent quality controls to give superior adhesive strength, higher durability and strong bond between blocks.

The unique combination of raw materials and a very efficient mixer enables this mortar to be thinner as well as versatile.

KON_CRETE Ready-to-use mortar ensures adequate bond strength and durability at only 3mm thickness against conventional sand – cement mortar where thickness is nearly about 10-15 mm. It contains no materials that may create health hazard.

Usages

FLYASH BLOCK (AAC PROCESS) have great workability; they have high flexibility in cutting / sawing, shaping, nailing and drilling using hand and power tools. It’s easy to handle due to its low density and can effectively reduce construction labor cost and time. Here’s how you can use FLYASH BLOCK (AAC PROCESS):

- FLYASH BLOCK (AAC PROCESS) offer a wide range of finishing options like tile hanging, timber cladding, brick slip systems or other rendering options like Ceramic tiling, Paint and Dry Lining.

- FLYASH BLOCK (AAC PROCESS) and panels have excellent acoustic performance and can be used as an effective sound barrier for conference halls, IT offices, schools, hospitals, hotels and theatres.

- The FLYASH BLOCK (AAC PROCESS) are available in a range of strengths to suit most applications: – 3 N/mm2 - 5 N/mm2 for general housing needs.